-

Nix Dents & Dings

Inspect new cans before they reach the filler. Prevent leaks. Save cost.

Inspect new cans before they reach the filler. Prevent leaks. Save cost.

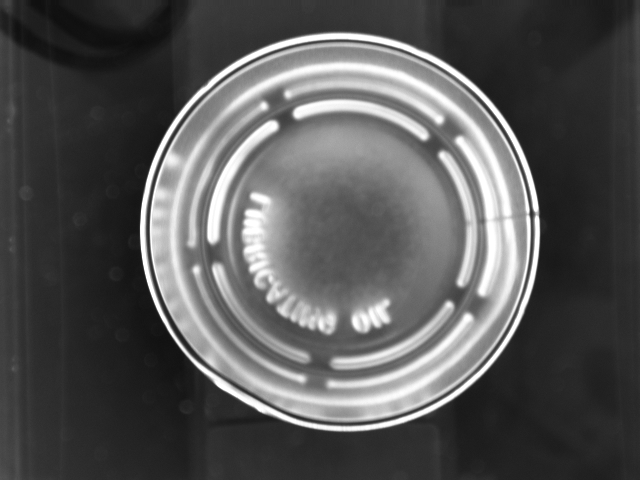

The Spectrovision ECI unit inspects the inner sidewall, base, and rim of cans for contaminates, damages and foreign objects. Production faults and transport damages are effectively rejected before reaching the filler, preventing loss of product and would-be faulty seams.

Verification of can labeling is also possible with Empty Can Inspection – please contact your local FILTEC representative with project specifications.

The Spectrovision base unit is a highly configurable vision system capable of a wide variety of inspection parameters. We love a challenge. Give us a call.

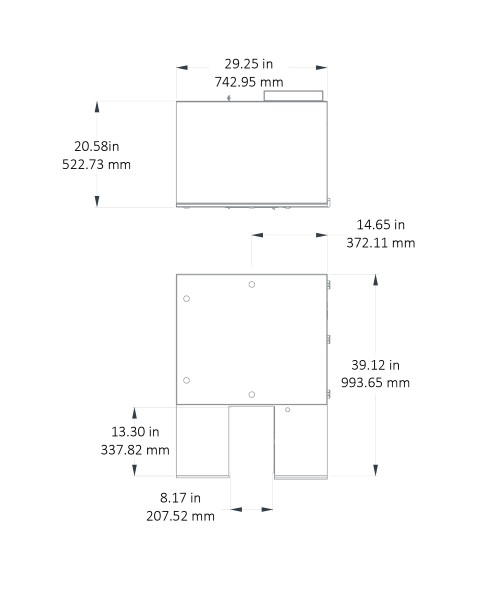

Techincal Details

For more detailed information regarding Empty Can Inspection capabilities, container rejection, and installation, please visit our Technical Documents library or contact your local sales representative.

GO TO LIBRARY REQUEST A QUOTE