-

Full Glass Container Inspection

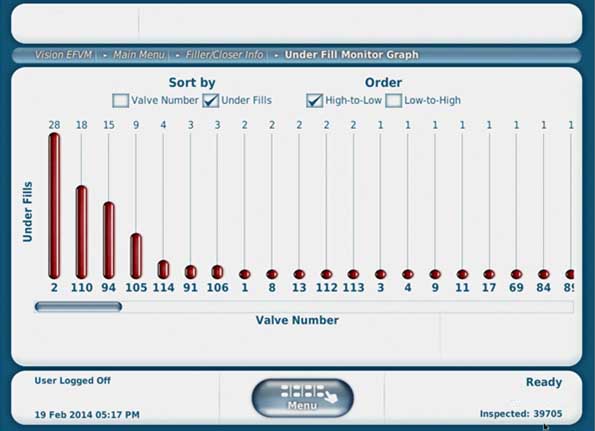

Identify and remove damaged and underfilled product before it reaches the consumer.

-

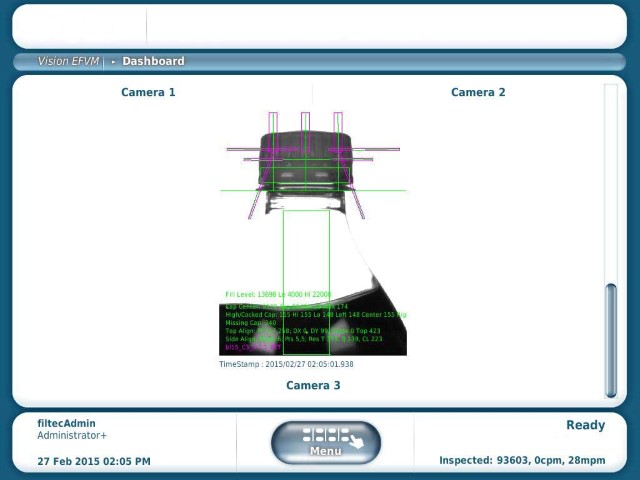

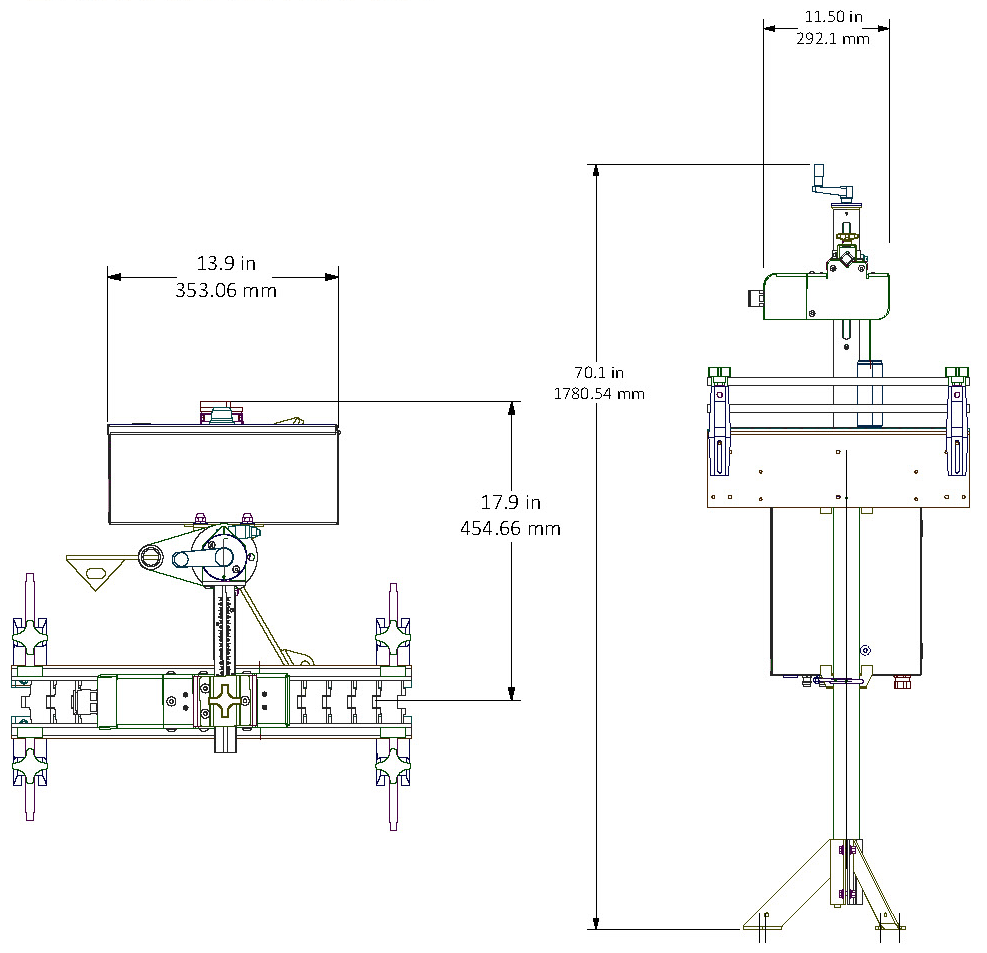

Perfection is in the Details

Comprehensive inspection of full glass containers, from crown to base.

-

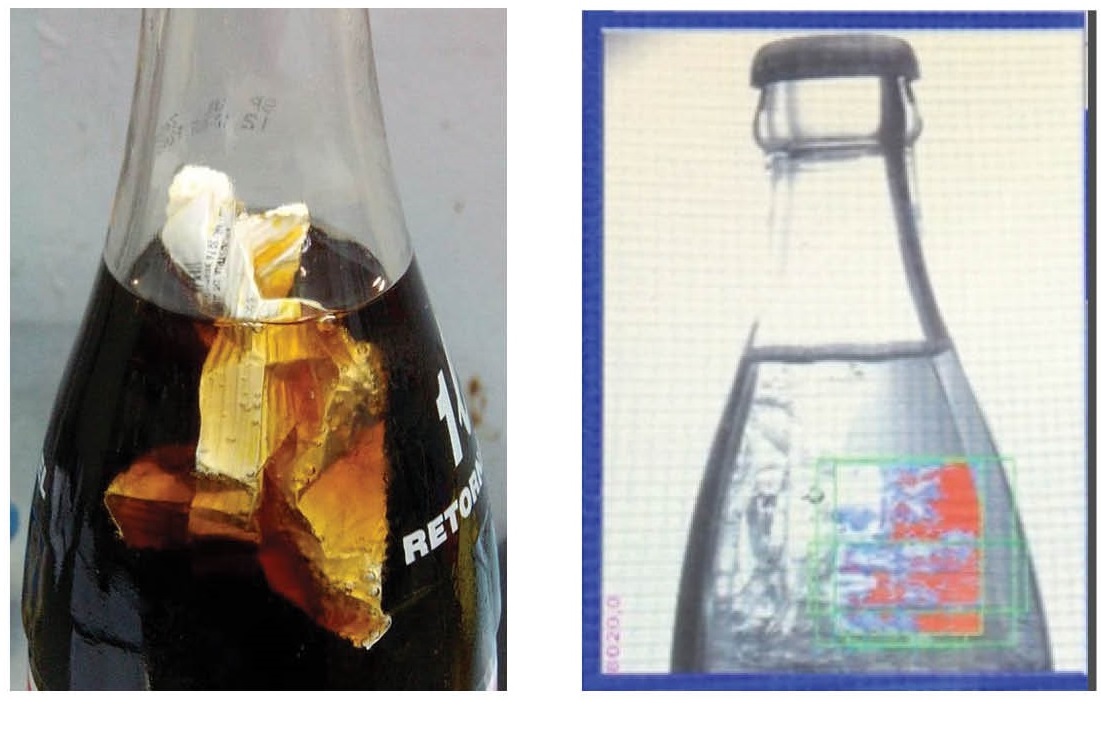

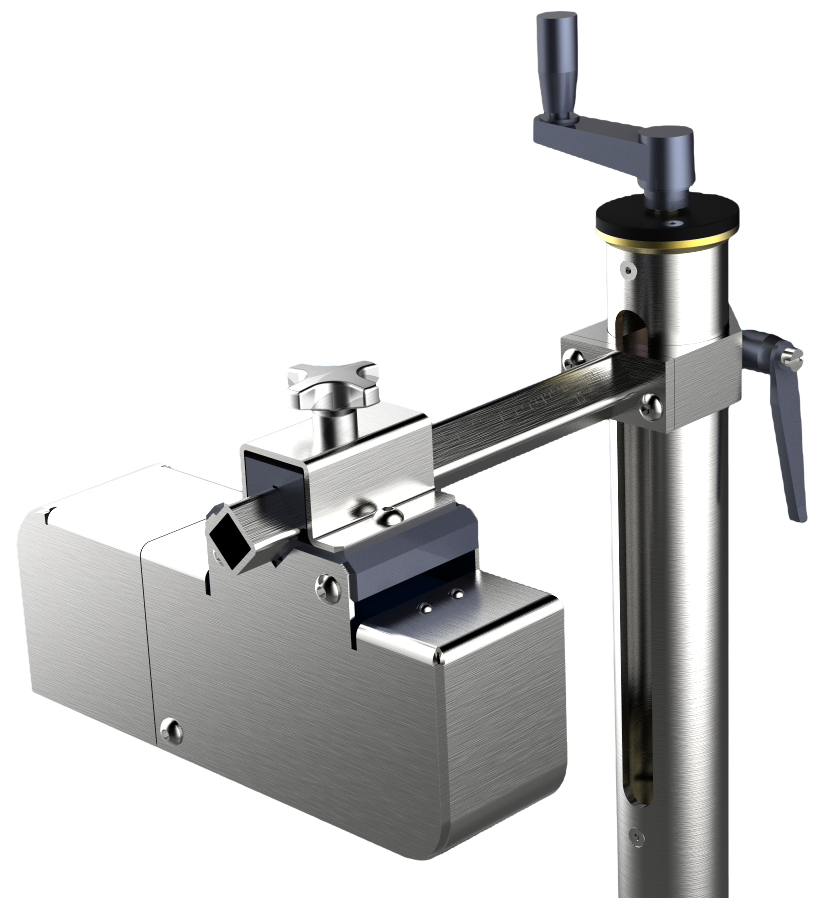

Floating Object Detection

Paper, plastic, straws, wood chips. We can catch anything that floats.