-

Empty PET Container Inspection

Catch imperfections in PET containers of all sizes before they reach the filler.

Catch imperfections in PET containers of all sizes before they reach the filler.

Imperfections in empty PET containers, either returnable or straight from the molder, can result in damaged or wasted product.

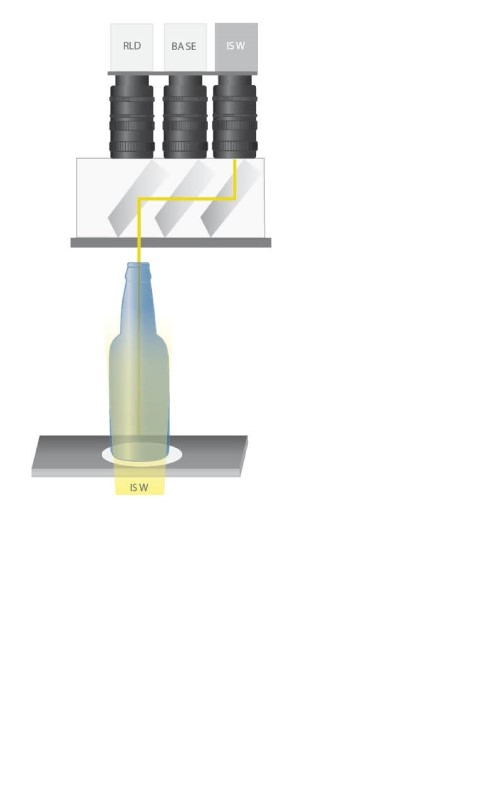

Outer sidewall refers to the outside surface of a container, usually below the thread and above the base. This outer surface can often become visibly scuffed or chipped, especially in REFPET, sometimes so badly these damages may result in leaks.

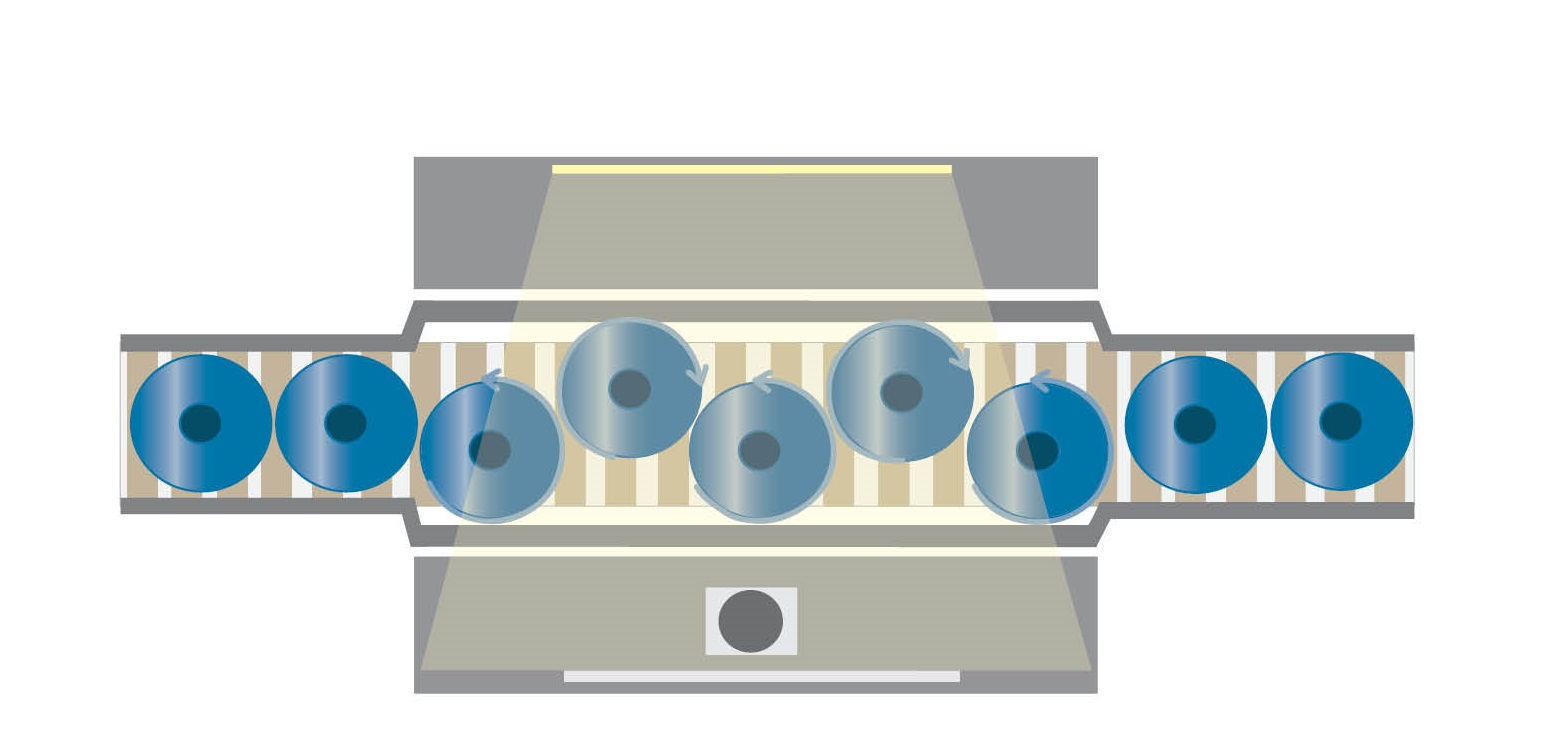

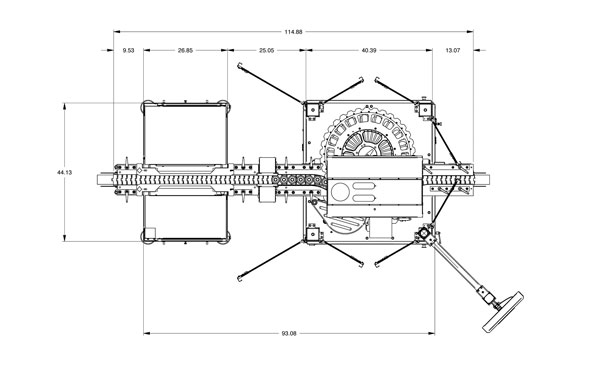

Twelve images are captured at 30 degree intervals while the bottles rotate past the inspection window, providing the most thorough inspection and fewest number of false rejects.

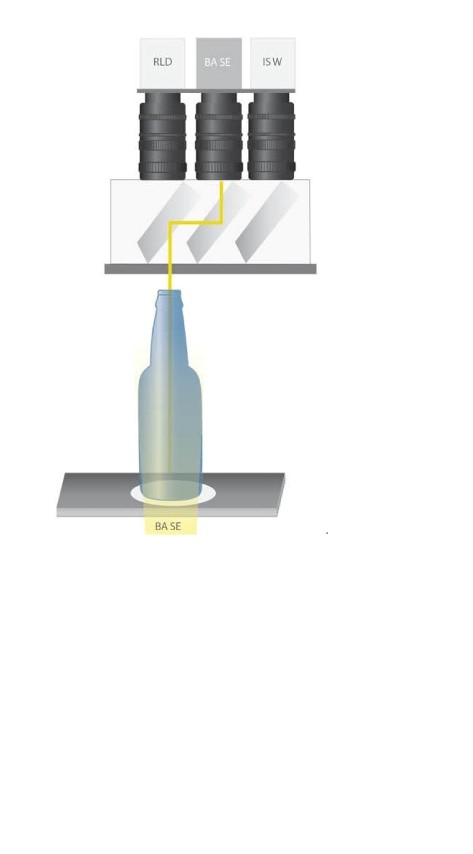

The base of a REFPET container is usually highly featured and therefore more susceptible to cracks and foreign objects that were not removed during the washing process. A base strobe and separate camera focus on this complex area to ensure defective containers do not reach the filler.

The bottle's inner sidewall includes all the inside surfaces of the container from the base up through the neck. Damages on these surfaces can be difficult to see, but can easily grow mold or develop cracks after the container has been filled.

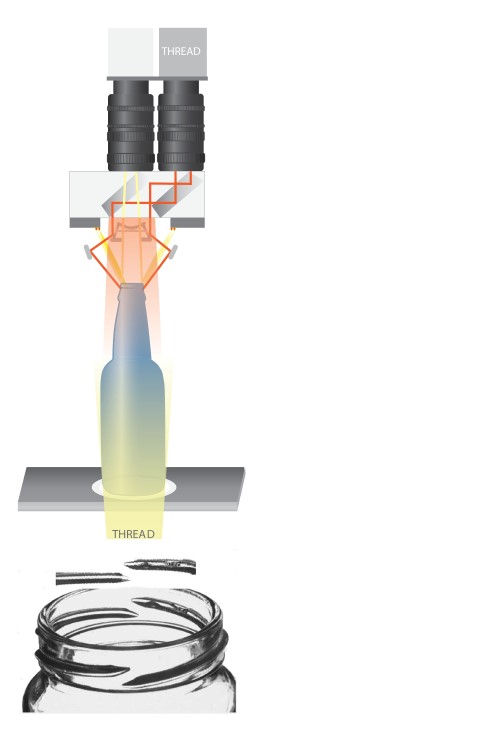

A bottle's thread is the molding at the top of the neck where the cap is screwed in place. Damaged thread can prevent the container from sealing properly, threatening pressurized or perishable product.

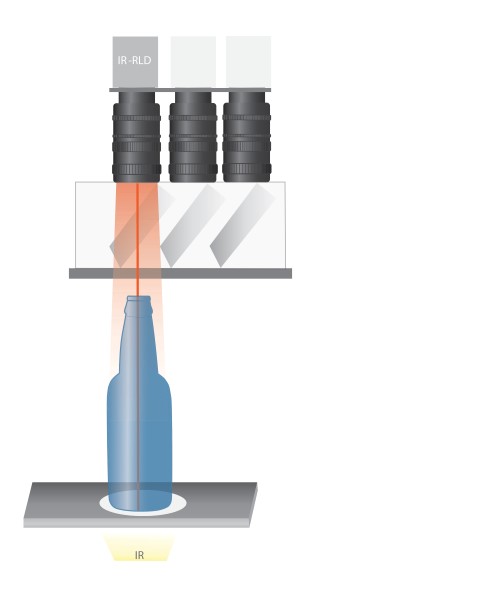

Without additional inspection, leftover caustic can occasionally remain inside of REFPET containers and contaminate the final product. FILTEC uses both radio frequency and infrared detection technologies to inspect REFPET containers for residual caustic.

Radio Frequency (RF) RLD Technology

Detects smallest amounts of caustic, even once it has dried

Infrared (IR) RLD Technology

Detects oil, paint, gasoline, and other liquids with low conductivity

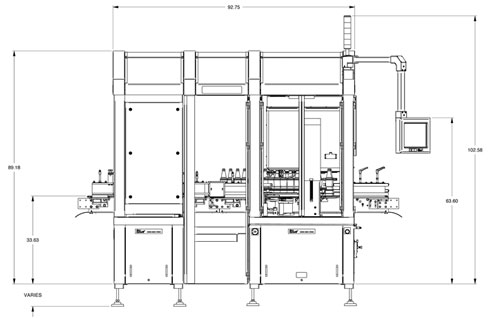

The latest evolution of FILTEC's long line of comprehensive empty bottle inspection systems.

Product Details

For more detailed information regarding Empty PET Container Inspection capabilities, container rejection, and installation, please visit our Technical Documents library or contact your local sales representative.

GO TO LIBRARY REQUEST A QUOTE