Rapid-fire full can inspection at speeds up to 2,400 containers per minute.

Rapid-fire full can inspection at speeds up to 2,400 containers per minute.

Flaws in filled aluminum cans can be alarmingly frequent and messy. Puncture holes left undiscovered can ruin full cases of product, and low-filled cans trigger customer complaints if allowed to reach the market.

Unlike most glass and PET containers, cans cannot be inspected with vision technology alone – FILTEC provides both x-ray and gamma based solutions for the reliable detection of non-visible can variables like fill level and pressure levels.

Finely-tuned fill level inspection on can lines is a complex marriage of speed and accuracy. FILTEC has been performing this rapid-fire dance for decades, ensuring that no empty or partially-filled cans reach the market and preserving consumer trust through countless millions of flawless containers.

We offer options of both gamma and x-ray source systems. Please contact your local FILTEC representative for help determining which works best for your market.

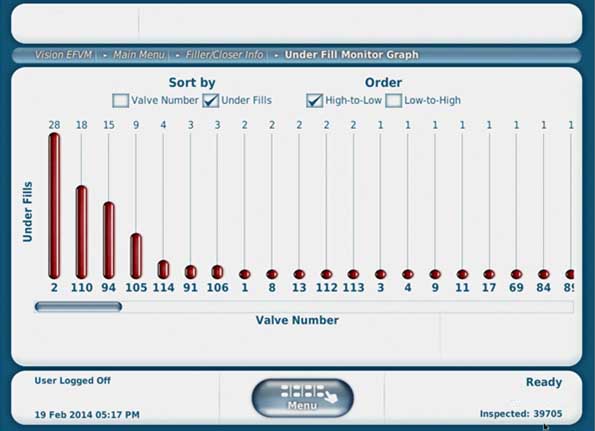

Incorrect fill level and faulty seaming can be a symptom of a poorly tuned filler valve or a failing seamer. We can help you track these flaws back to the individual filler valves and seamer heads so you can keep your lines fine tuned for maximum efficiency and minimal waste of product.

Faulty can pressure is often caused by dents, puncture holes, or improper seals.

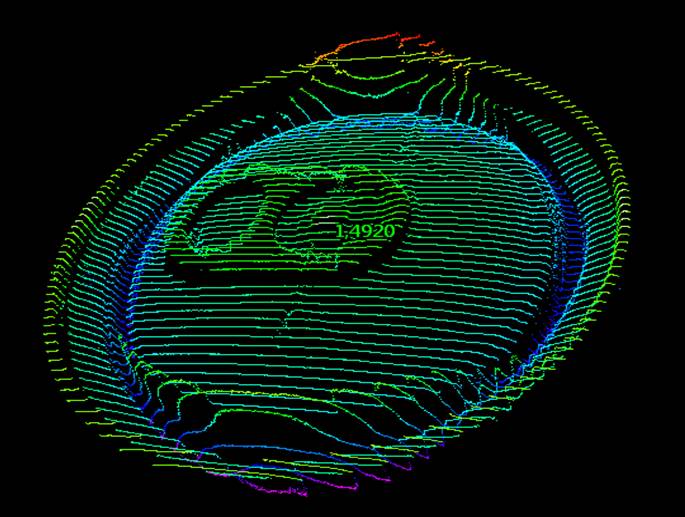

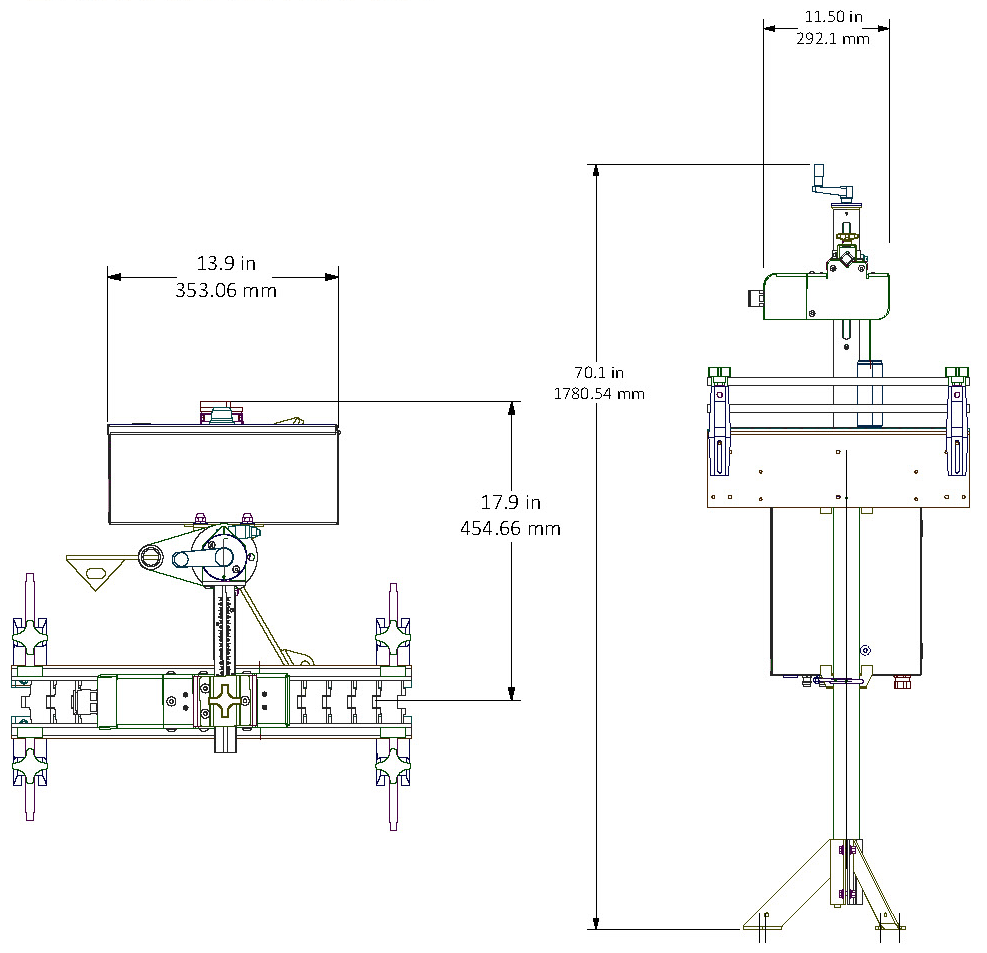

The AURAtec (New! Available Fall 2016) is a laser-based inspection system that distinguishes between low and high pressure containers by assessing acceptable pressure profiles. The AURAtec functions with nearly a six sigma detection margin at speeds exceeding 1,200 containers per minute.

FILTEC also provides high speed laser coding, code verification, and code detection equipment for cans. Our LASEtec 4 is a premier coder, built for high speed production and can reach speeds of 2,400 cpm with perfect accuracy.

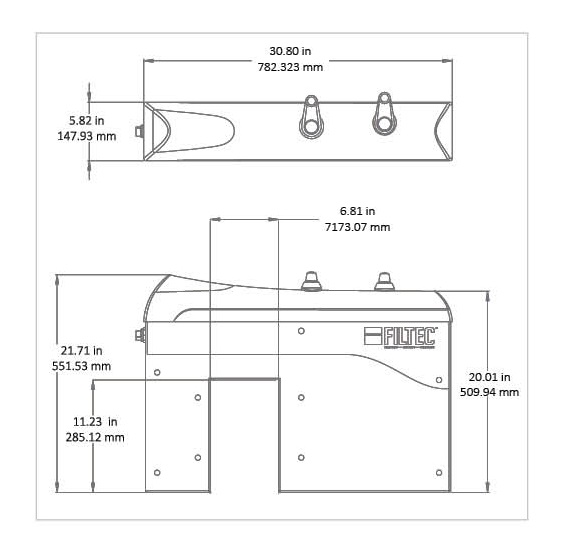

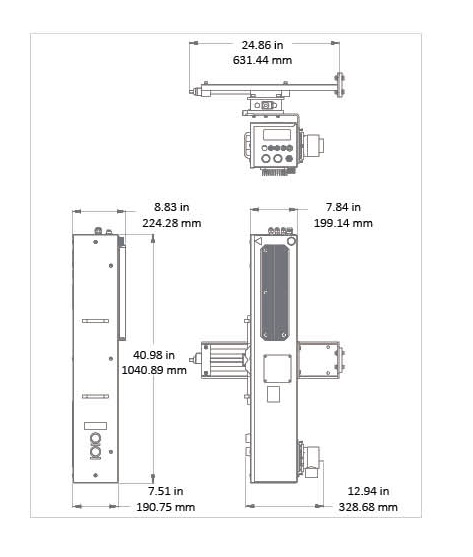

Compact. Efficient. The most reliable, high speed inspection solution worldwide for decades.

Meet the Filtec3.

Available in both X-Ray and Gamma configurations.

Fill level inspection with x-ray or gamma units.

Pressure detection with multi-point laser scanning technology.

For more detailed information regarding Full Can Inspection capabilities, container rejection, and installation, please visit our Technical Documents library or contact your local sales representative.

GO TO LIBRARY REQUEST A QUOTE