Identify and remove damaged and underfilled product before it reaches the consumer.

Identify and remove damaged and underfilled product before it reaches the consumer.

Imperfections in full PET containers can result in millions of dollars of wasted product and consumer complaints. A rigorous quality control and line analytics program can prevent damaged product from reaching the end customer and maintain streamlined, effective line operation.

LINE ANALYTICS AND OPTIMIZATION

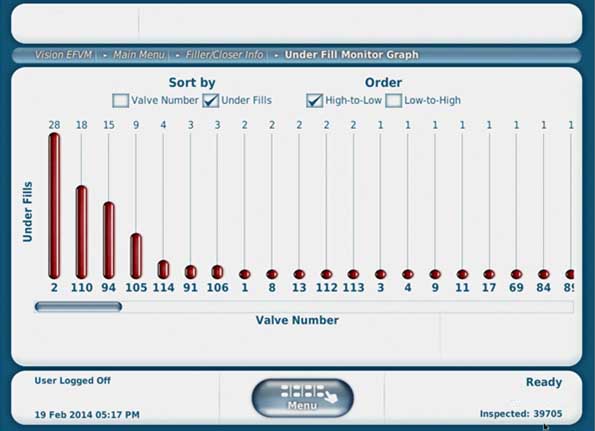

Closely monitoring filler and capper performance keeps high speed line operations smooth. FILTEC systems can identify underperforming or broken valves and capper heads within seconds. Immediate warnings prevent wasted product, container damages, and line failures. Analytics provide detailed foundations for line planning and optimization.

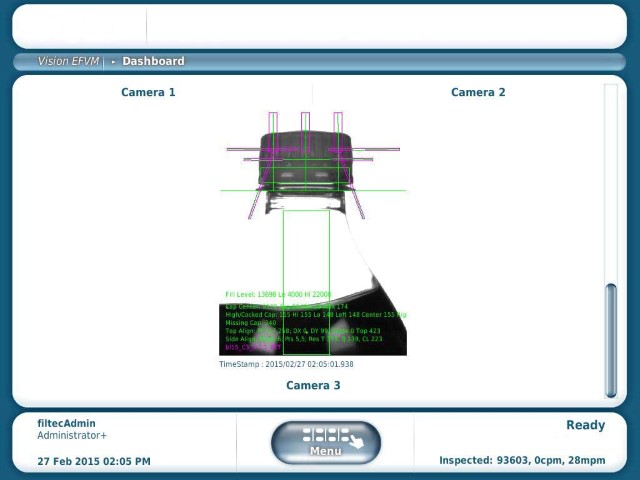

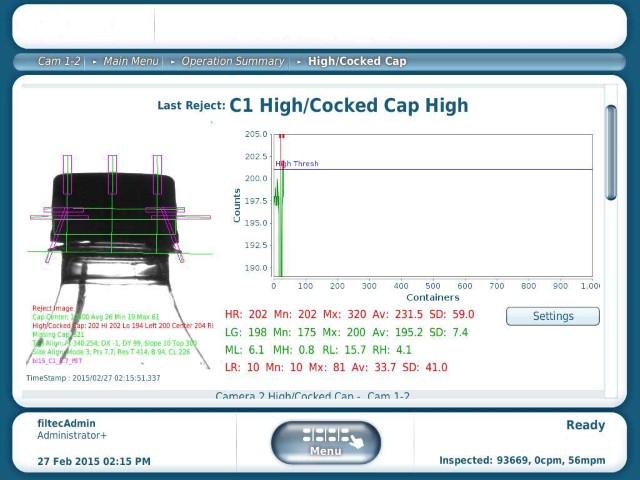

Fill and pressure levels, especially in carbonated or pressurized containers, can be a crucial indication of product integrity. FILTEC's finely tuned vision systems can isolate multiple inspection parameters simultaneously, detecting fill level down to less than a milliliter.

FILTEC's PLD, or Pressure Leak Detector, is a sensor-based system that detects bottle pressure as an indicator of container integrity without the risk of adding any additional pressure to the container itself.

Incorrectly applied caps and broken tamper bands can cause pressure to leak from the container and can cause the spoilage of certain products.

FILTEC equipment can also inspect for cap color, ensuring that branding remains consistent throughout the production process.

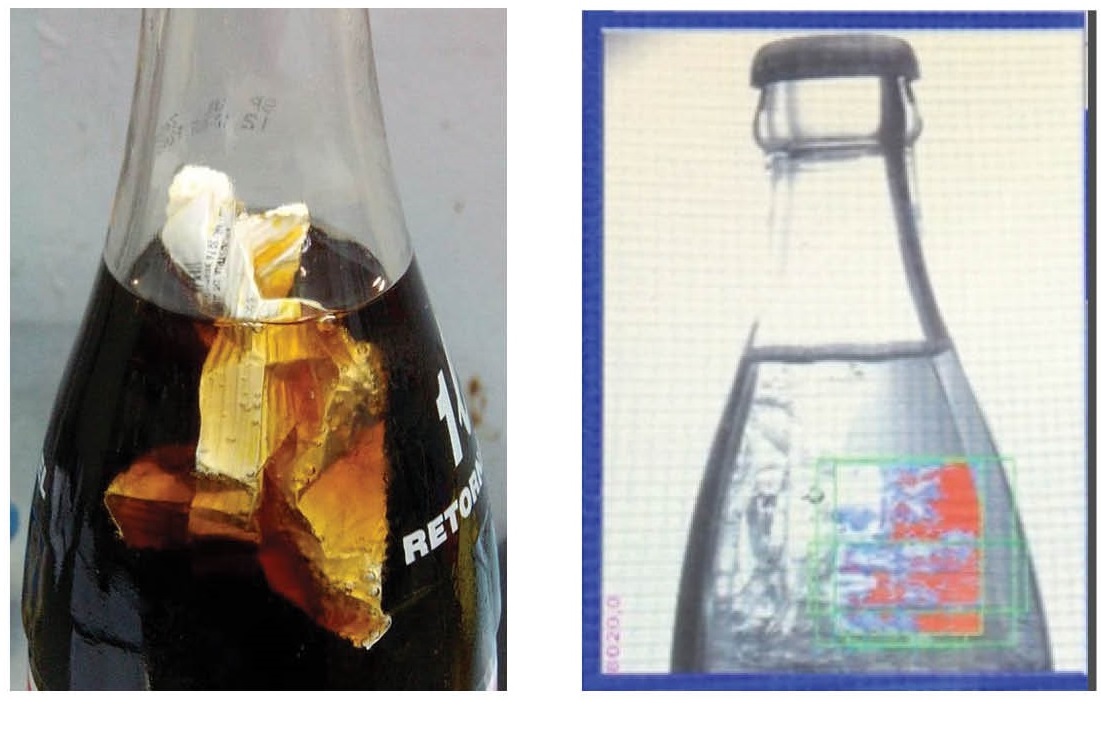

Large objects may remain stuck in returnable containers after the washing process and float hidden in the necks of filled containers. In dark liquids, clear plastics and bits of paper may be difficult or impossible to see, but with powerful strobes FILTEC equipment can pick them out easily.

Every product is a little different. We have a full arsenal of inspection solutions - all of our machines are programmed specifically for the application. The tighter the programming, the more accurate the inspection.

Let us know what types of inspection you're looking for and our engineers can start developing an inspection unit tailored for your line.

Advanced, modular vision system to fulfill a wide variety of inspection requirements including fill level, closure, and label inspection.

X-ray and gamma based fill level inspection systems.

For more detailed information regarding Full PET Container Inspection capabilities, container rejection, and installation, please visit our Technical Documents library or contact your local sales representative.

GO TO LIBRARY REQUEST A QUOTE